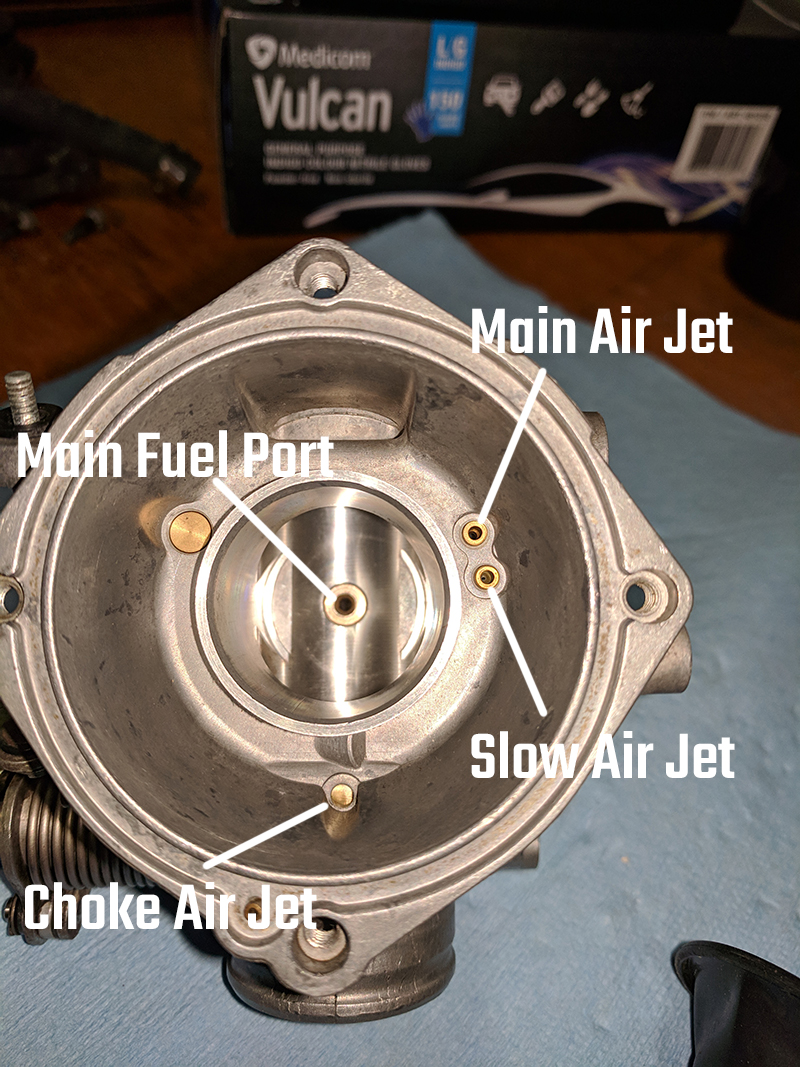

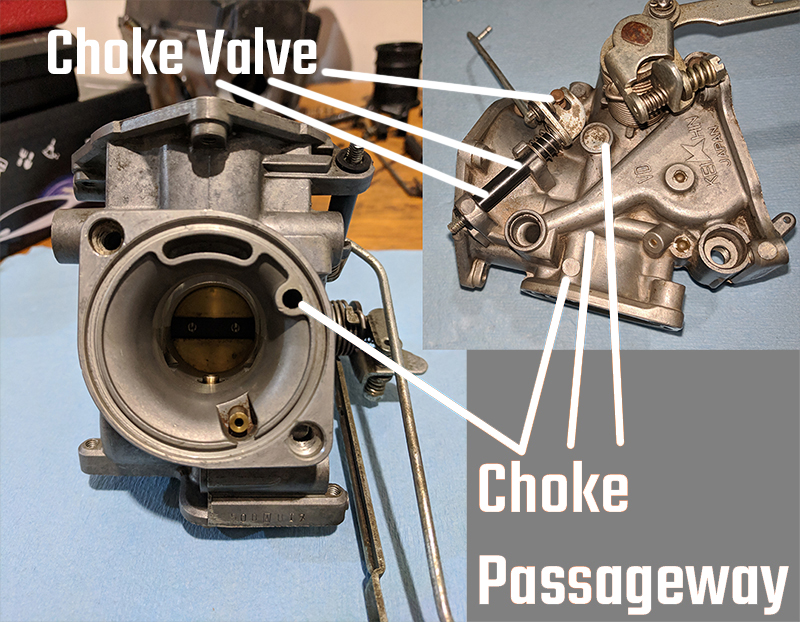

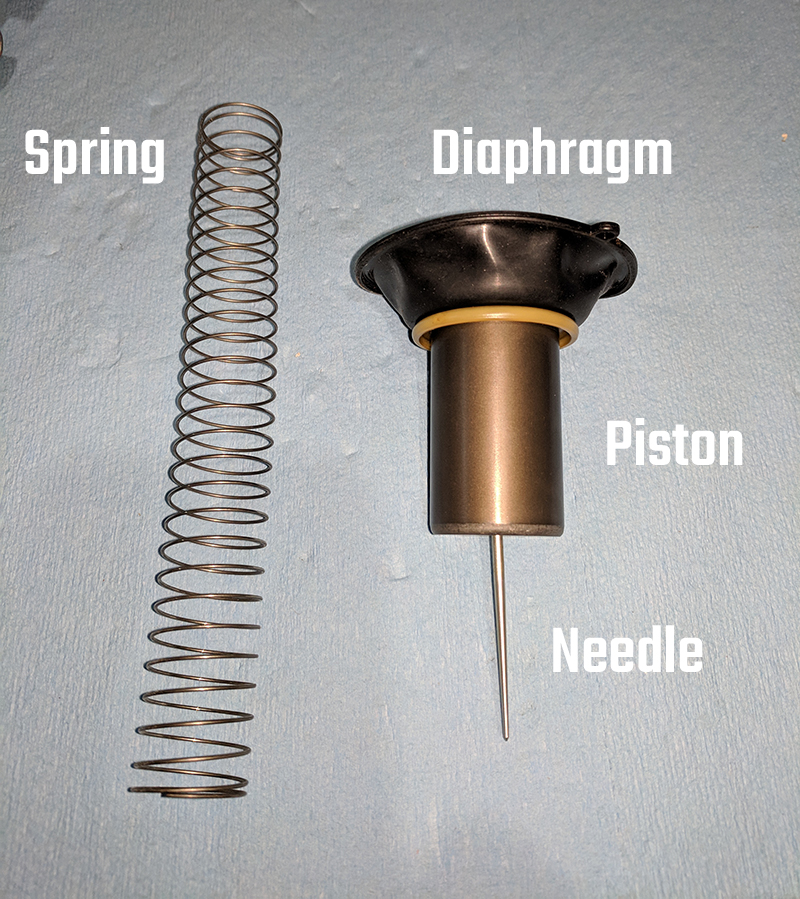

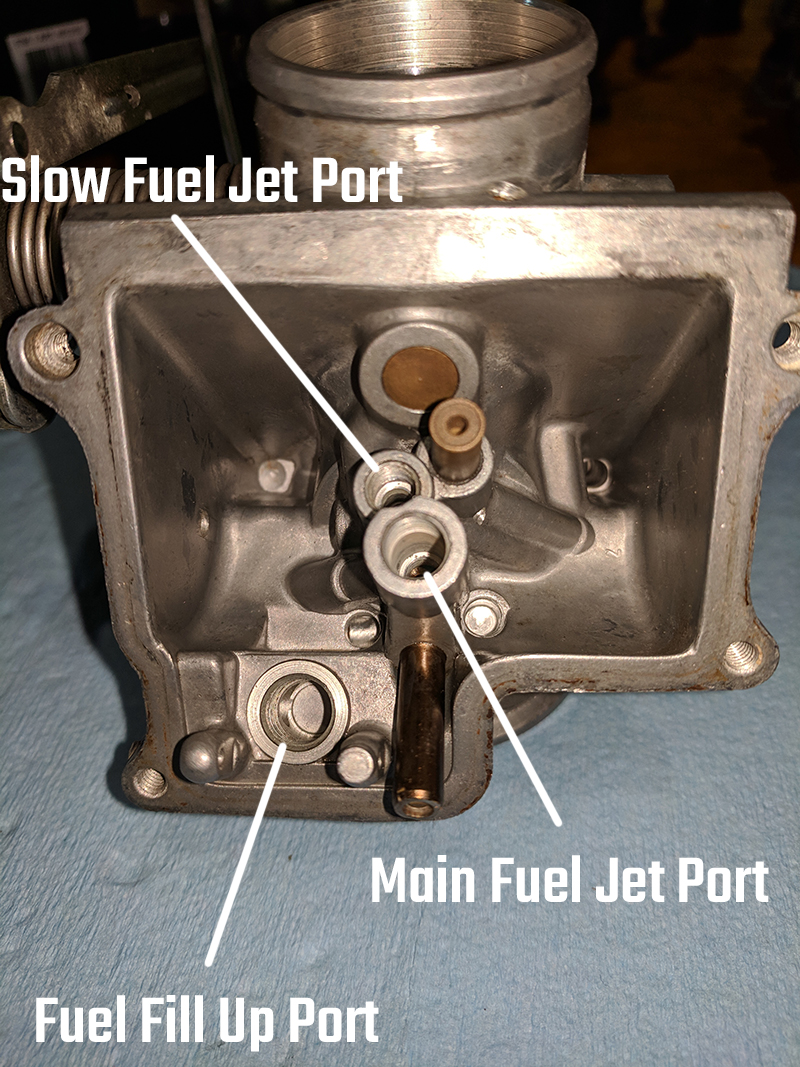

Lets begin by defining the components of the carburetor first:

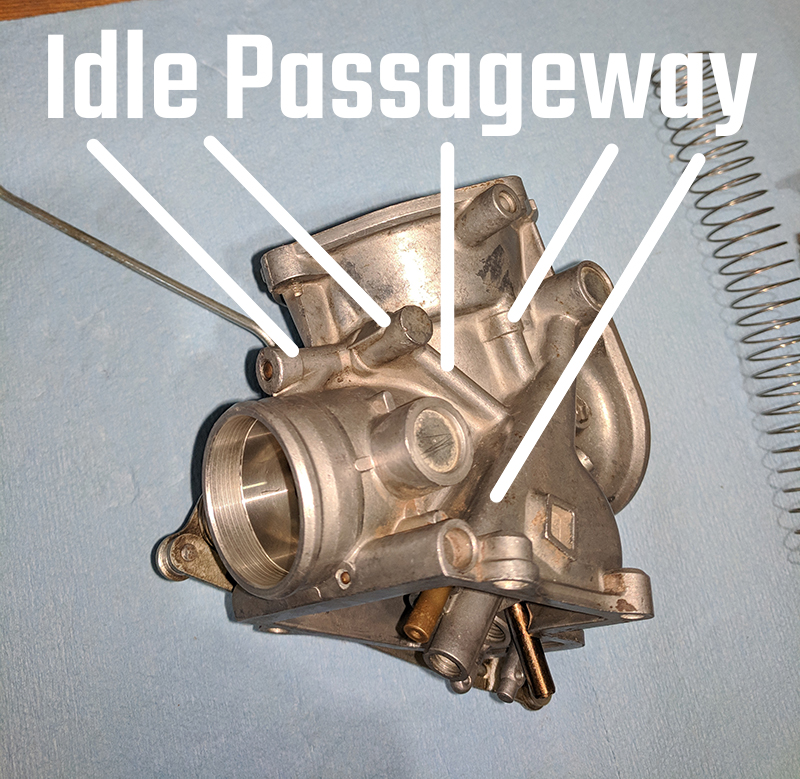

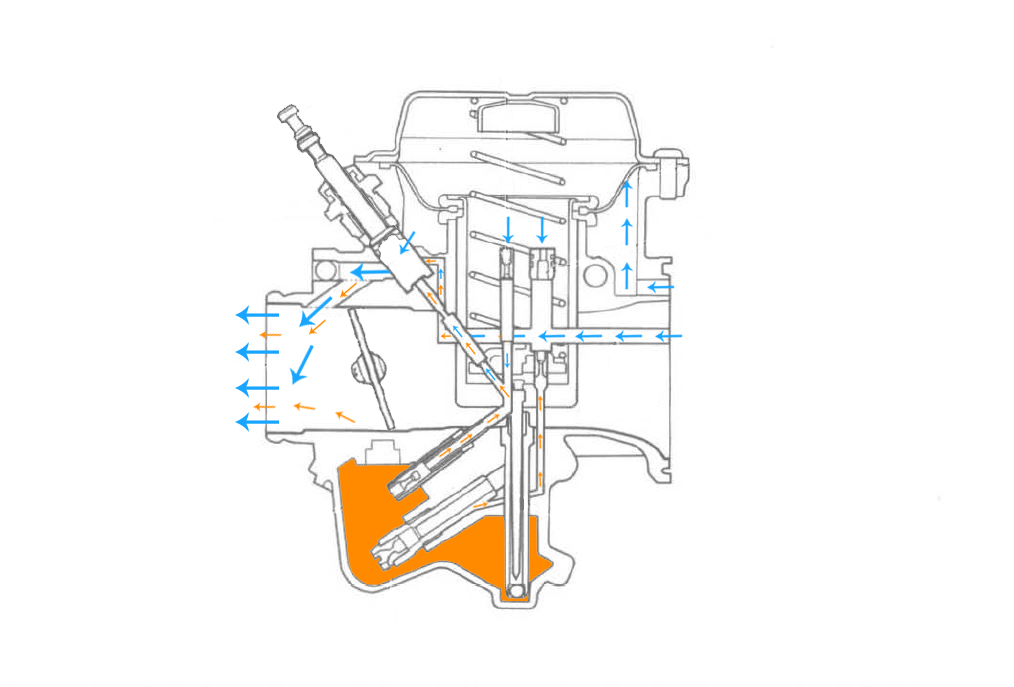

The start cycle of the motorcycle begins with having the throttle fully closed and the choke fully open. When the starter turns over that creates vacuum in the idle and choke passageways.

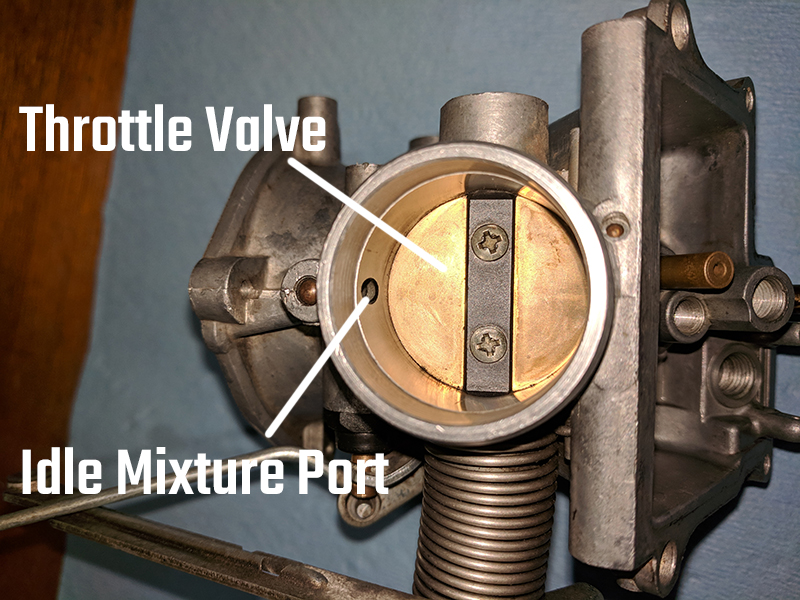

That vacuum draws air in through the slow air jet, the choke air jet, and the choke passageway. Similarly fuel is sucked up through the slow fuel jet as well as released from the idle mixture port.

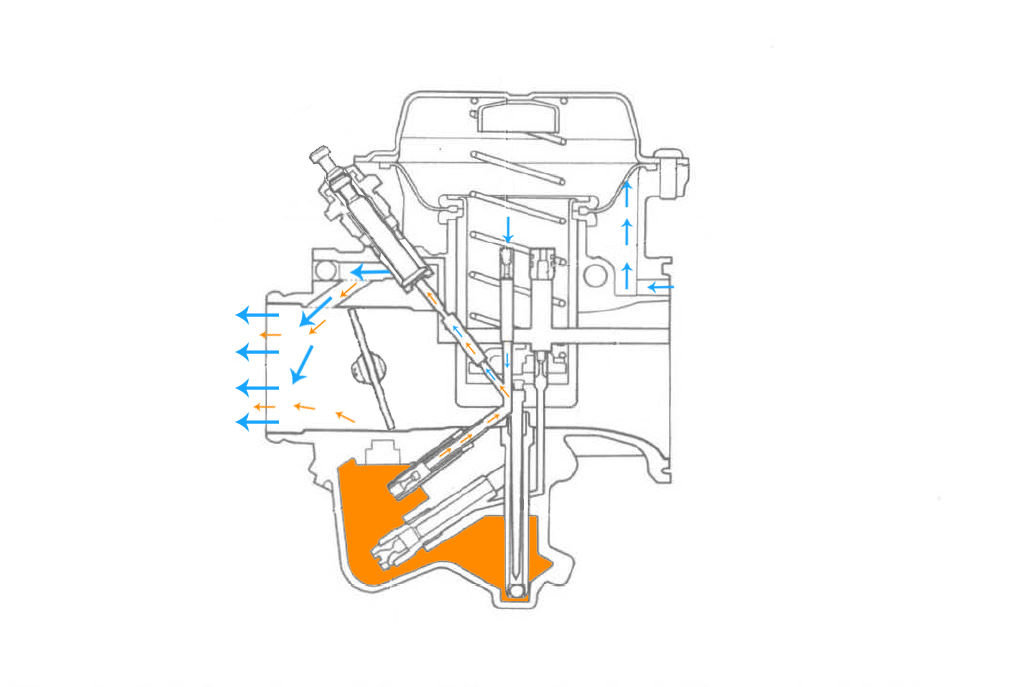

As the mixture undergoes combustion in the cylinders more vacuum is created and more mixture is drawn in. The cycle repeats and the system is able to idle. At this point the rider would usually wait for the engine to warm up and then close the choke valve. This will result in a number of changes in the flow dynamics of the carburetor. Firstly the choke passageway would become completely closed off. Which also means that the choke air jet is also closed. That would leave all the air coming into the diaphragm chamber only one place to go. Down into the slow air jet. The slow air jet will push air into the idle passageway mixing along with the fuel coming in from the the slow fuel jet.

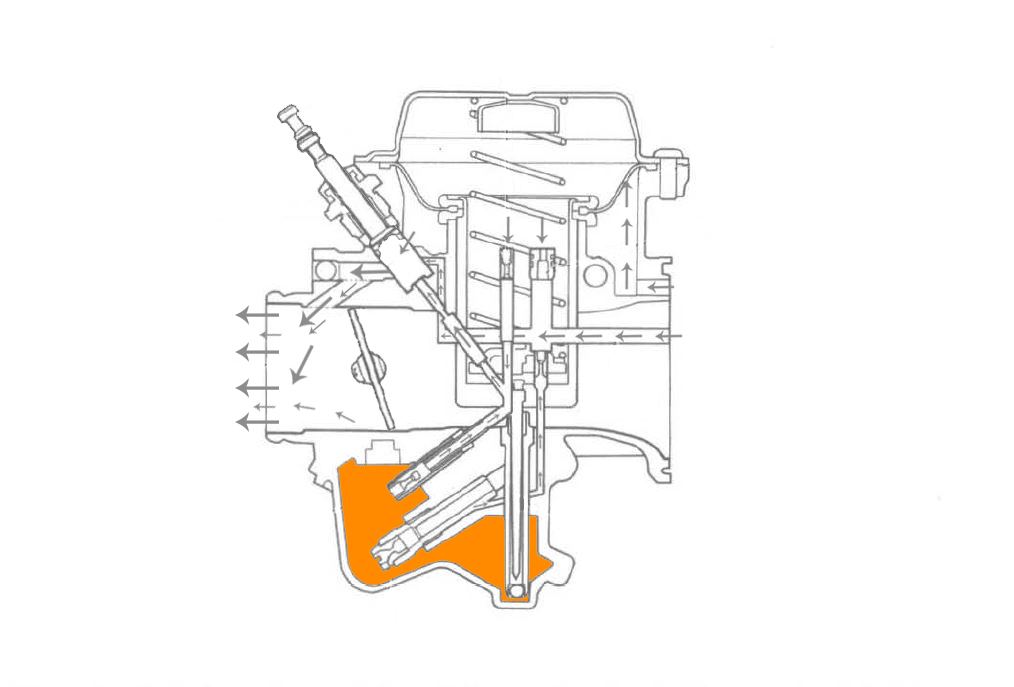

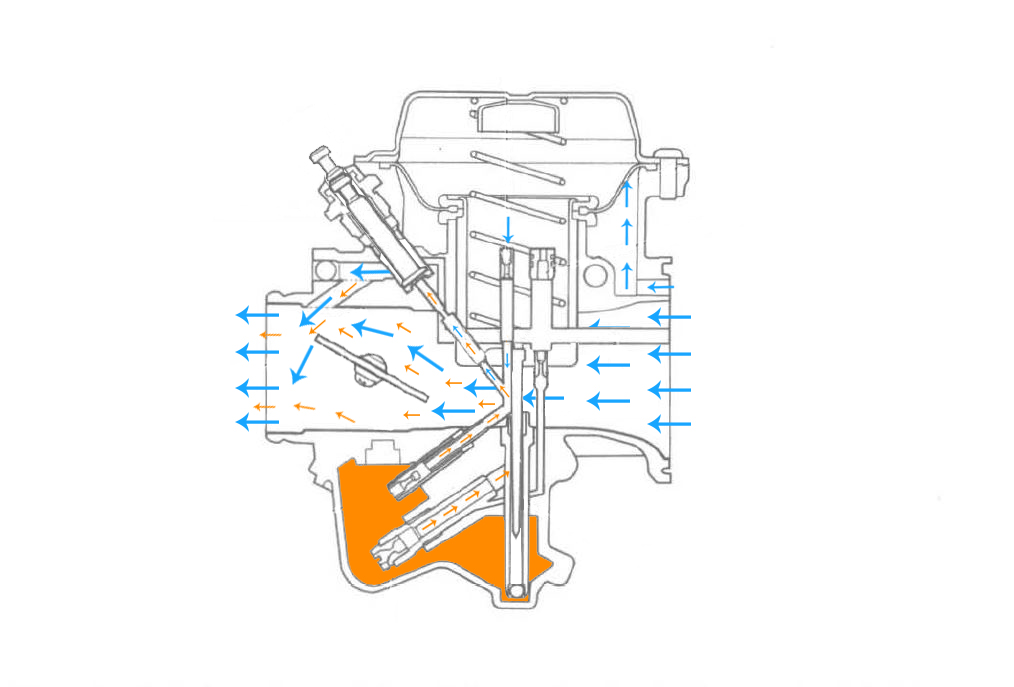

Now that we have the engine idling the throttle can finally be twisted. This action will pull on the cable attached to the throttle valve, which would turn it. Once the throttle valve is open, a huge vacuum is created down the main air way, which in turn sucks in more air through the intake and into the passageway to the diaphragm. So much so that the air pressure build up in the diaphragm chamber applies a force counter acting the force applied by the spring in the piston. This makes the piston raise up, compressing the spring, and pulling the needle out of the main fuel port. As that happens the pressure in the diaphragm chamber now has one more place to go, the main air jet. Since that main fuel port is open fuel and air from the primary fuel jet and the main air jet can flow freely out of.

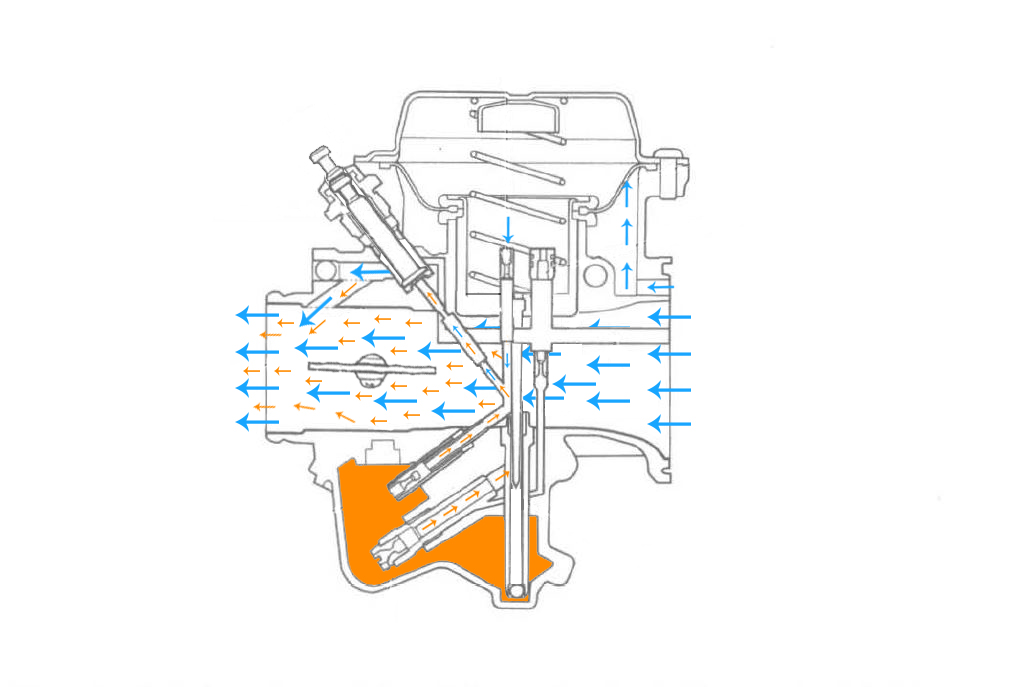

Now we have the cylinders receiving much larger amounts of fuel and air, making the combustion stronger, driving the RPMs up. The wide open throttle case is essentially the same thing, but the piston is completely retracted up. The needle is at its top most position creating the biggest possible opening in the main fuel port. Such that the biggest amount of fuel and air the carburetor would allow can flow into the engine.

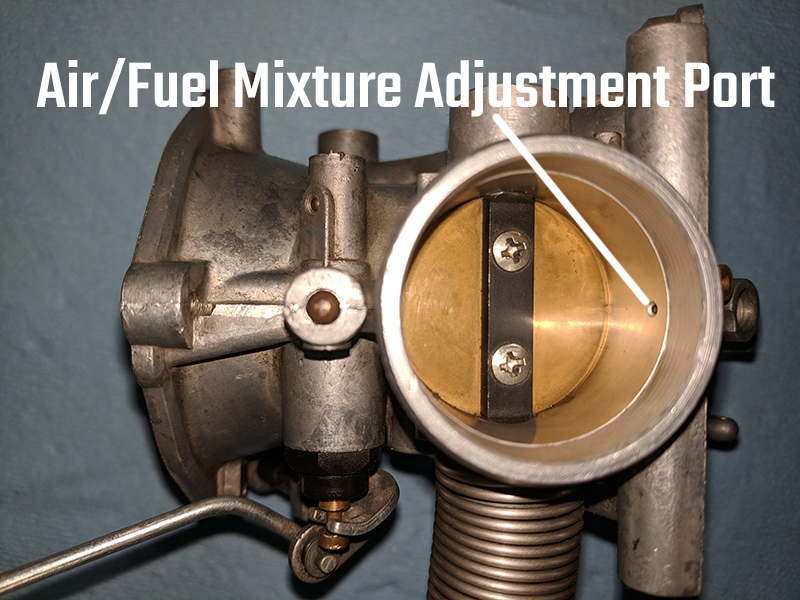

As you see carburetors are simple yet very complicated. That is why if not maintained properly they can be very problematic. For example you may have an engine that starts and runs under higher rpm fine, but will stall almost immediately if left to idle. That is usually a sign of there not being enough fuel sprayed into the cylinders. Which could be as simple as dialing in your air/fuel ratio with the regulating screw. Or it could be that your slow fuel jet is clogged. The second being the more likely of the two. Having contamination in your fuel due to rusting of the interior of the gas tank or just garbage in the fuel, or ripped or torn or no air filters that suck in dust and all sorts of other garbage, would be the primary causes for clogging your carbs up. As for problems in the higher RPMs, there you could be running into lack of or too much fuel due to under/over sized fuel jets. Similarly lack of or too much air could be an issue if the stock air box is modified or replaced. Ignition problems and other electronics trolls are possible as well. All perfectly avoidable if the motorcycle is used frequently and the carbs properly maintained and cleaned.

Now just because you got one carburetor working that doesn't mean your engine will run fine. It is very likely that if you are building a cafe racer you would be building on a motorcycle with more than one cylinder. Hence more then one carburetor as well. This would imply that the carburetors need to be treated as one unit. That means that the linkages between them for the choke and throttle need to be adjusted to move each carburetor's components the same amount at the same time. Synchronizing the carburetors is very important for a smooth running engine in all rpm ranges.